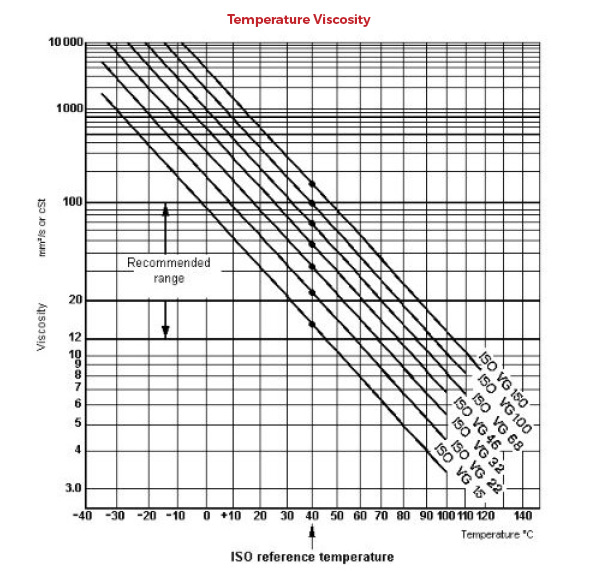

In order to eliminate an external application during processing, higher molecular weight PDMS materials, with viscosities ranging from 10,000 cSt to 60,000 cSt, have been used as internal additives in thermoplastic polymers to give processing advantages and surface property improvements. They are characterized by their low pour points, volatile nature (evaporate in open system), stability at low temperature, low surface tensions (high spreadability), low viscosity‐to‐temperature coefficients (viscosity changes little even at extremely low temperatures), low molecular weight, low viscosities (all close to water), high dielectric strength and refractive index values ranging from 1.3750 to 1.3900.Due to their volatility (varying rates of evaporation), low surface tensions (high spreadability) and non-greasy feel, they are used as base fluids, carrying agents and wetting agents in a wide range of personal care products. Super Low Viscosity Pure Silicone Fluids are clear, colorless and odorless linear polydimethylsiloxane fluids that range in viscosities from 0.65cSt (i.e.thinner than water ) to 2cSt (centistokes) 25☌. These low viscosity PDMS meet the Federal Specification VV‐D‐1078 “Silicone as damping fluid ” and are used in a wide range of military, industrial and avionic gauges, meters, instruments and monitoring systems. VOC exempt fluids for renewable energies.Low dielectric constant fluids for photonics.California VOC ,exempt replacement for petroleum based solvents that are not VOC compliant.Refractive index (RI) values between 1.3970 to 1.400.Low viscosity change at temperature (low VTC).Low surface tension fluids (high spreadability).The physical and chemical properties are illustrated in table. They will not contribute to ozone-depletion and global warming. Low viscosity PDMS fluids are exempt from federal VOC regulations, including California (CARB) and OTC regulations. They are used in a wide range of military, industrial and avionic gauges, meters, instruments and monitoring systems. For instance, Clearco low viscosity pure silicone fluids meet Federal Specification VV-D-1078 “Silicone as Damping Fluid”. Due to their low pour points and low viscosity change at temperature, they are excellent choices for low temperature bath fluids. They are excellent lubricants for plastics, foams and rubbers.

Low viscosity PDMS fluids also possess high resistance to shear, high water repellency, low vapor pressure and low reactivity.

#HIGH VS LOW VISCOSITY SKIN#

Applications may include:Īntiperspirants, skin creams, skin lotions, suntan lotions, bath oils, hair care products and so on. They are characterized by their low pour points, low surface tensions, low viscosity change at temperature, excellent lubricity, high dielectric strength, refractive index values between 1.3970 to 1.4000, wide service temperature range and inertness to virtually all substrates Ī primary use is as an ingredient in a number of personal care products due to their low surface tension, skin lubricity, high spreadability and non-greasy feel. Low viscosity pure PDMS fluids are clear, colorless, and odorless that range in viscosities from 5cSt to 20cSt (centistokes) 25☌. Low molecular weight PDMS polymers, with viscosities less than 1000 cSt, are used extensively by the plastics industry as external release agents applied on the mold surface prior to injection molding. As rubber portion of a thermoplastic vulcanizate material, the cross-linked silicone rubber imparts novel properties, such as lower hardness, reduced coefficient of friction and improved low and high temperature properties. As additives, silicones, and in particular polydimethylsiloxane (PDMS), are used to improve mold filling, surface appearance, mold release, surface lubricity and wear resistance. Polydimethylsiloxanes are used in the plastics industry as additives for improving the processing and surface properties of plastics, as well as the rubber phase in a novel family of thermoplastic vulcanizate (TPV) materials. Posted in Silicone Recycling High and low viscosity PDMS

0 kommentar(er)

0 kommentar(er)